Hydraulic fracturing technology has been around longer than you may think.

Directional drilling and hydraulic fracturing changed the American energy industry. Over the past decade, the “shale revolution” has turned the global market on its ear. With this new attention, one may think these technologies are brand new – but they have their beginnings before the telephone, phonograph and light bulb.

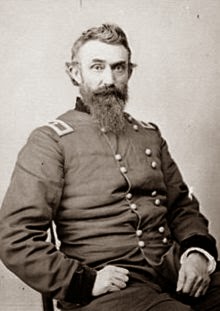

The Civil War and Torpedoes

In the middle of the 19th century, Colonel Edward Roberts of the 28th New Jersey Volunteers (and the Union Army of the Potomac) witnessed firsthand the destructive power of war. During the Battle of Fredericksburg, he watched rounds of artillery decimate a small canal in the battlefield. The water in the canal seemed to amplify the effects of the artillery shells. Following the war, he patented the first system for what we recognize today as hydraulic fracturing.

Colonel Roberts’ system was somewhat less refined than today’s method: it involved packing a “torpedo” case with 20 pounds of powder. The torpedo was lowered into the well, with a couple of wires attached. The borehole was then filled with water, and the two wires completed a circuit, causing an explosion of the subterranean case.

The operation cost $200 (and shares to 1/15 of the extra production) – and reportedly increased production to the tune of 1200%. Later torpedoes would be filled with nitroglycerin, until the 1930s, when less explosive materials were used for subterranean fracturing.

In 1949, Halliburton completed two experimental sites that most closely resemble modern hydraulic fracturing. By the mid-60s, it was a rapidly growing technique. Beginning commercially in Oklahoma, it soon found its way to the Denver, Green River and San Juan Basins. In his 1975 State of the Union address, President Ford even mentioned shale oil resources as part of his extended energy plan.

More War and Theft

Directional drilling is another important component of modern day oil shale extraction. While it has newer techniques than Colonel Robert’s torpedoes, debates about directional drilling have been happening for over a century.

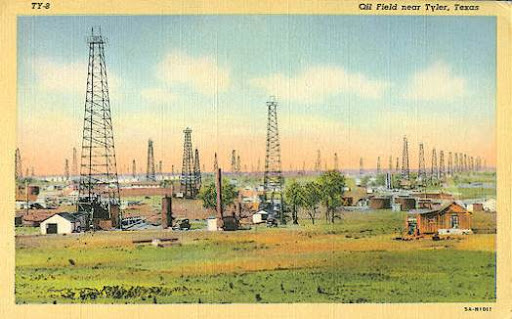

Accusations of “slant drilling” were a precursor to the Kuwait/Iraq conflict that led to the Gulf War. The same sort of accusations are also a colorful part of East Texas oilfield history. In the middle of the last century, some unscrupulous drillers stole an estimated $100 million of oil using directional techniques. At the same time as the East Texas oil thievery, purposeful directional drilling was being heavily studied.

Accusations of “slant drilling” were a precursor to the Kuwait/Iraq conflict that led to the Gulf War. The same sort of accusations are also a colorful part of East Texas oilfield history. In the middle of the last century, some unscrupulous drillers stole an estimated $100 million of oil using directional techniques. At the same time as the East Texas oil thievery, purposeful directional drilling was being heavily studied.

Gyroscopic surveying soon came into practice, helping to improve knowledge of wellbores’ directions. New techniques were invented. Water jets could break up soft formations and mud motors were finally refined from a 1930 design. Many of today’s techniques reach back to this time, over seventy years ago. The practice of Magnetic Steering was later introduced in the 1970s.

Putting It Together

A son of Greek immigrants finally put these two techniques together into one package.

George P. Mitchell, the father of modern day hydraulic fracturing, experimented for years before putting together the safe, cost-effective process in use today. While Mitchell was primarily concerned with harnessing natural gas, oil sands have also proven highly profitable using his techniques. The Potential Gas Committee at the Colorado School of Mines estimates that the shale revolution will supply the nation’s energy demands for 100 years.

Technology continues to change and evolve. And leading the way is Select. Select has offered complete water solutions in support of safe, and economically beneficial hydraulic fracturing practices for over a decade. The company was borne out of a need in the field, and knows the processes of hydraulic fracturing inside and out.

Far away are the days of blindly lowering a torpedo into a pit. And what interesting challenges lie ahead for hydraulic fracturing? Sometimes the newest ideas just need a little inspiration from the past.