Cementing Chemicals

Fine tune cement slurry performance with cementing additives that improve bonding and boost the wellbore stability of your next well.

Select is an Innovative Leader in Well Cementing Technology

Our comprehensive selection of innovative and fit-for-purpose cementing additives safeguard every customized slurry for the demanding conditions encountered in any wellbore scenario.

Engineered to perform with precision and accuracy, especially for zonal isolation, our premier cementing chemistries reduce the risk of costly remedial work down the line.

Our Cementing Products Include:

Fluid Loss Additives

Gas Migration Control Additives

Suspension Agents

Foaming & Defoaming Agents

Retarders

Lost Circulation Materials

Spacer Technology

Surfactant & Solvents

Dispersants

Accelerators

Specialty Chemicals

Targeting Challenges with Solid Solutions.

Prevent loss circulation and ensure well integrity

Our specialized cementing chemistry optimizes the interaction between spacers, surfactants, and loss circulation materials (LCMs), effectively minimizing fluid loss and maintaining wellbore stability.

Manage fluid densities to mitigate the risk of induced fractures

We provide tailored solutions for specific flow zones, such as those containing salt, CO2, or other fluids, to meet unique well conditions.

Slurry systems designed for unique zone conditions

Compatibility between mud and spacers requires rigorous testing to prevent viscosity issues. Our lead to tail focus on rheology hierarchy helps prevent issues like strength retrogression at high temperatures, in order to maintain cement integrity.

Mechanical properties designed for fracturing and production

Whether it’s the ability to withstand cyclical loads and maintain tensile strength or performance during stage perforation, our goal is to design cement that can sustain the productive zone’s operations over an extended period.

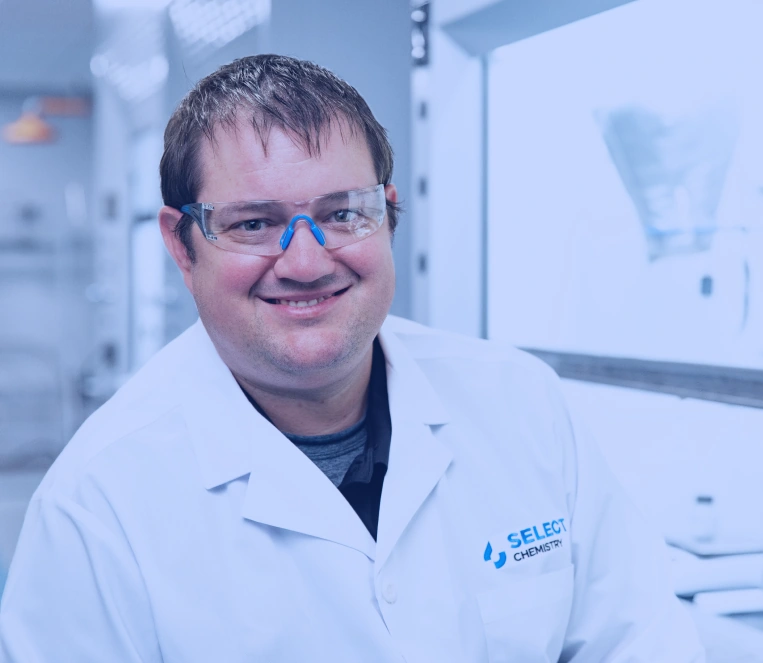

Deliverable Customization from Lab to Field

Our state-of-the-art laboratory is equipped with the latest technology and staffed by oilfield industry experienced chemists and engineers who can provide comprehensive testing and analysis in addition to cement slurry and spacer design support, delivering quality assured results.

With our advanced testing and analysis techniques, we can help you optimize your cementing designs, reduce risks and increase operational efficiency.

Comprehensive API Testing And Evaluation

Analytical and Quality Control Testing

Engineered Formulation and Design Evaluation

Manufacturing Efficiency

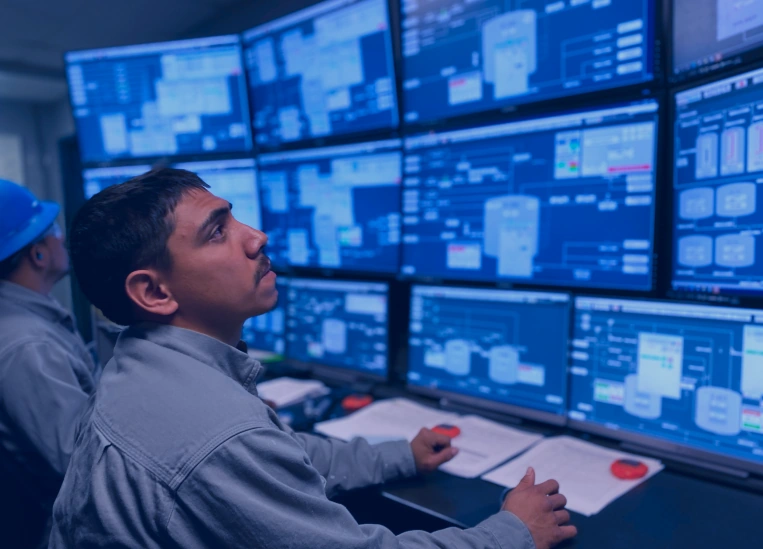

Our understanding of cementing chemistry improves our manufacturing processes and creates efficiency at scale. We streamline our manufacturing with automation controls and process indicators to reduce energy use and minimize batch waste.

Our labs work with manufacturing operations to regularly review and identify off-spec inventory avoid compromising performance. This allows us to reduce waste and emissions from transport.

Performance Delivered

We recognize the vital role that efficient and reliable transportation plays in delivering cementing chemicals for oilfield operations, and we’ve invested in advanced logistics infrastructure dedicated to providing timely and secure transport of these critical materials.

Our logistics fleet includes a range of assets, such as bulk pneumatic tankers, flatbed trailers, and purpose-built chemical transport vehicles. These units are specifically designed for the safe loading, handling, and delivery of cementing chemicals.

To provide real-time oversight, we implement advanced tracking technologies that allow you to monitor shipments throughout the entire delivery process, giving you full transparency and confidence in your cementing chemical logistics.

Related Resources

Connect with a

Chemistry Expert

Our team consists of highly skilled professionals specializing in cementing chemicals and logistics, with extensive training to offer expert advice and implement efficient chemical handling and delivery strategies.